LMI’s AI-powered

anomaly detector sets

the stage for advanced

inspection solutions

Smart Vision systems

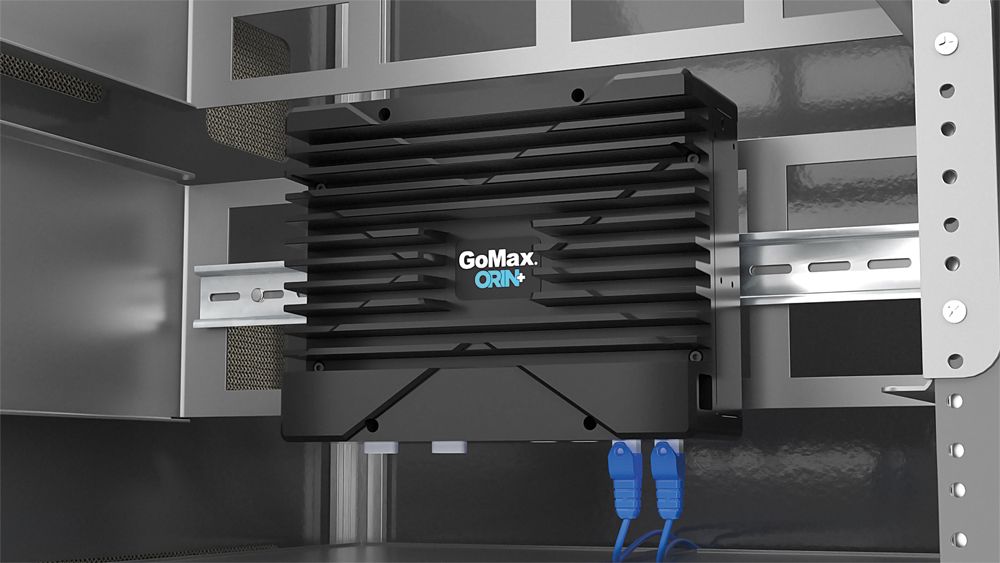

As part of LMI Technologies' commitment to innovation, the GoPxL Pro Tools series introduced the Anomaly Detector, a powerful AI-powered toolset designed to enhance 3D defect detection in production lines. This solution leverages traditional and AI-based tools within the GoPxL software framework, enabling users to train and deploy defect detection models directly on GoMax hardware without relying on additional cloud or external resources.

The Anomaly Detector sets the stage for advanced inspection solutions based on LMI’s IoT-enabled vision inspection software platform. It addresses the growing demand for advanced inspection and defect detection solutions across industries such as automotive, food, building materials, tires, and more. It empowers manufacturers to address evolving challenges in defect detection, improve production quality, and reduce costs. With its AI-driven capabilities and seamless integration with LMI’s Gocator and GoMax hardware, the Anomaly Detector is a critical tool for industries aiming to stay competitive in a rapidly changing manufacturing landscape.

Benefits

The Anomaly Detector provides significant advantages over traditional inspection methods:

• Detect Features of Varying Shape and Size with high speed and accuracy: Eliminate the need for manual threshold tuning by training models on datasets of OK and NG parts.

• Streamlined Workflow: Integrated tools reduce file and dataset management overhead, saving time and effort.

• Cost and Time Efficiency: Train and update models directly in production without additional development licenses.

• Enhanced Measurement Capabilities: Pass anomalies to subsequent tools for precise measurement and gauging based on user-defined criteria.